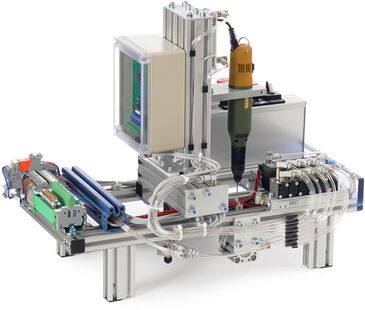

Drilling and milling station

Drilling and milling machine to mill the recess in the bottom part of an IMS® workpiece. The milling machine can be controlled with two different feeds.

- Milling head

- Milling spindle, 5,000 – 20,000 rpm, controlled by 0...10 V internally or externally

- Potentiometer for internal speed setting

- Position sensor

- Clamping cylinder

- Valve block 5 x 4/2-way solenoid valves

- Milling feed cylinder, Z-axis

- Milling feed cylinder, x-axis

- Milling feed cylinder, Y-axis

- Stop cylinder, double-acting

- Control console with the following components:

- Selector switch for speed setting

- Potentiometer

- Indicator light

- Emergency stop with indicator light

- PLC port via 25-pin SUB-D connector

- PLC requirements: 8 x digital outputs, 11 x digital inputs, 1 x analog output for speed (can also be controlled via potentiometer)

To ensure functionality and guaranteed lifespan for the pneumatic components and controls, maintenance work needs to be carried out on the following: filters, pressure control valve and pressure display plus lubrication.