CarTrain Common Rail with VTG

CarTrain Common Rail with VTG provides an effective and efficient learning environment using a variety of media relating to automotive engineering. It is based on the latest methods and educational experience and utilises the possibilities offered by modern technology. The combination of various media in a learning platform offers trainees a comprehensive view of engine management systems and guides them towards a deep and genuine understanding.

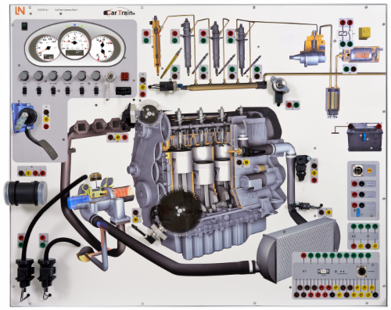

The system combines hardware and software with good educational logic. The hardware for the experiments consists of authentic components used in real vehicles. Each component is observed in a realistic setting both as an individual element and as part of the engine management system as a whole. The components are connected via two control units, which pick up the signals from the sensors connected in the system and trigger the actuators as appropriate. This allows the overall process of an input-processing-output (IPO) model to be represented as it is used in practice. Various driving situations can be studied. The sensors and actuators of the engine management system are all authentic components and are fully functional.

The accompanying software includes the full training curriculum and uses multimedia to illustrate the components present inn the hardware. The whole system is covered in the course, including its open and closed-loop control circuits as well as the individual sensors and actuators. In addition, students are continuously challenged to interact with the equipment. Extensive instructions for experiments and measurements using the components are also included.

The fact that the training system is fully wired ensures that it can be instantly deployed and put to use.

Training contents:

- Power supply

- Engine control unit for a Common Rail system

- Sensors in a Common Rail system, design and function

- Actuators in a Common Rail system, design and function

- Design of Common Rail system

- Interaction between components

- How the system’s closed-loop control systems work

- Interpretation of circuit diagrams

- Use of circuit diagrams

- Interpretation of nominal and target data for vehicles

- Use of target data in measurements

- Development of diagnostic skills

- How to use measuring instruments typically employed in vehicle repair shops

- Practical measurements on components in the engine management system

- Use of standard diagnostic routines

- Limitation of errors and faults by the following means:

- Testing functionality

- Use of sensory perception

- Read out from fault memory

- Measurement and testing of electric, mechanical and pneumatic variables

- Setting up engine management systems

- Technical communication

- Preparation of test logs, evaluation and documentation of results

- Flow of information between data transmission systems

- Expert systems and telediagnostics

- Use of hotline

- Programming control units via Ethernet

- Default values and resetting of control units

The training system includes the following:

- Authentic components made by various vehicle manufacturers

- Hardware and software for theory and practical lessons

- Software for self-directed study and demonstration

- Predefined tests and results

- Computer-based theory studies using 3D animation

- Computer-based measurements in practical experiments

- Fully operable OBD interface

- Connection to any testers typically used in shops via OBD and diagnostic CAN

- Switchover between real and simulated operation for sensors

- Fault simulation capabilities via PC, covering more than 30 faults

The system includes a programmable control unit, which universally supports and processes various parameter sets by loading the requisite software settings:

- Operating voltage

- Air intake temperature

- Engine temperature

- Crankshaft revs

- Intake mass-flow rate

- Cam shaft signals

- Rail pressure

- Charging pressure

- Fuel pump control

- Exhaust gas recirculation

- Glow-plug control

- Accelerator setting

Virtual instruments

- Interface with multimedia experiment – measurements can be copied to the course instructions via drag and drop

- Simultaneous measurement of at least two voltages and current

- Oscilloscope function handles three channels with simultaneous multimeter display

- Measuring ranges: V<250 V=/~, I<15 A=/~ measured directly from the circuit

- Circuit range protected by automatic fuse

- USB port

Electrical terminals use 4-mm safety sockets. Pins are logically labelled. All measurement sockets are colour-coded, which is beneficial to the educational effect. Sensor signals, control signals for actuators and power supply sockets are each coded in a different colour.

The training system has a compact design. The housing is made of high-strength metal. Front and rear panels comprise pressed laminate panels, 5 mm thick, with tough melamine resin coating on both sides. The background colour of the panels is RAL7035 (light grey). Dimensions are approximately 800 mm in height and 1000 mm in width. On the front the engine block and system components are pictured using high-contrast, UV-resistant colour printing. The UV-resistant ink retains its colour even when exposed to sunlight. A special method involving an addition lacquer coat ensures that the equipment is durable and scratch-resistant without adversely affecting the clarity and legibility of the printing on the front panel. The rear is protected from contact by a cover plate. The housing can be modified into a special wheeled mode. Alternatively the housing can be set up directly on a bench or table on secure feet.

Includes:

- Training system with mains connection, 110V-240V AC, 50-60 Hz

- Integrated measurement hardware

- A 12-14 V power supply is built into the housing

- Set of measuring leads

- OBD diagnostic tester

- USB cable

- CD with basic software

- Operating instructions

System requirements:

- Personal computer with Windows 10 (32- or 64-bit version)

- CD-ROM drive for installing software

- USB port for connecting measurement hardware

Technical data:

- Dimensions: 980 x 780 x 210 mm (WxHxD)

- Weight: 40 kg