HPC Continuous Valve Technology - Proportional Hydraulics

HPC Continuous Valve Technology - Proportional Hydraulics

Technical know-how and solutions expertise in industrial applications flow seamlessly into the modular training systems of Lucas-Nülle. Comprising hardware as well as interactive multimedia courses (ILA), they provide practical hands-on knowledge. Via the USB interface, the hardware can be directly controlled from the multimedia course, the interactive schematic diagram editor can be opened, and the measurement values can be recorded at all times. The training systems are perfectly matched to the qualification levels of industry and education institutions.

Through logically structured, practical exercises, the trainee should:

- Understand physical laws for proportional valves such as pressure difference, opening area and flow rate

- get to know and apply the legal requirements and safety regulations, apply the most important symbols of proportional hydraulics, read circuit diagrams,

- get to know and understand the meaning and mode of operation of setpoint specification, ramp function and signal sequences practice the adjustment, commissioning and optimization of an electrohydraulic system,

- Determine characteristic values and derive characteristics from them.

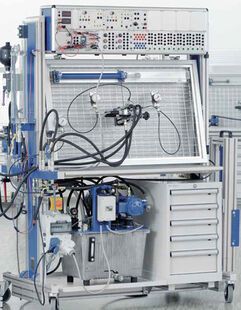

To teach hydraulic know-how in vocational and advanced training, Lucas-Nülle offers various workstations with grids for the clean and safe mounting of industrial components, along with different learning topics. The standard components used at the workstation are the same ones students will later encounter in machines and systems during their professional careers.

Learning content:

Through logically structured, practice-oriented exercises, the trainee will:

- Understand physical principles in proportional valves such as pressure difference, flow cross-section, and volume flow

- Learn and apply legal regulations and safety standards

- Apply the most important symbols of proportional hydraulics and read circuit diagrams

- Understand the meaning and function of setpoint input, ramp function, and signal sequences

- Practice the adjustment, commissioning, and optimization of an electrohydraulic system

- Determine characteristic values and derive performance curves

Further project tasks from the field of switching and electrohydraulics:

- Identify components

- Commissioning

- Function of a pressure relief valve

- Control of a hydraulic cylinder via a directional control valve

- Simulate loads on the hydraulic cylinder using a throttle check valve

- Influence of inlet throttling on the travel speed of a hydraulic cylinder

- Influence of changing system pressures on the travel speed of a hydraulic cylinder

- Influence of changing load pressures on the travel speed of a hydraulic cylinder

- Effect of outlet throttling (pressure intensification)

- Function of a pressure reducing valve

- Drive unit/pump

- Directional valves and actuators

- Shut-off valves

- Flow control valves

- Pressure valves and pressure switches

- Hydraulic accumulators

- Application circuits

- Commissioning and maintenance

- Hydraulic power unit

- Hydraulic pump/variable pump characteristic

- Differential cylinder/pressure intensification

- Differential cylinder/flow rate

- Cylinder, load pressure

- Adjusting cylinder speed

- Check valve

- Check valve with hydraulic release

- Adjustable throttle valve

- Throttle check valve

- Flow control valve

- Pressure relief valve, direct operated

- Pressure relief valve control

- Pressure reducing valve

- Pressure switch

- Pressure switch / hysteresis

- Hydraulic accumulator

- Differential circuit

- Rapid traverse/creep speed control

- Valve sequencing control

- Commissioning, inspection, maintenance, troubleshooting, repair